What Type Of Nails For Cement Siding

How to Install Fiber Cement Siding

Updated: Jul. 14, 2021

How to cutting, nail and install durable fiber siding, plus caulking and painting tips.

Half the price of a fiber cement board siding job is labor, and so yous tin save thousands of dollars by installing it yourself. A siding pro shows the tools and tricks needed for a weathertight installation.

You might also like: TBD

- Time

- Complexity

- Cost

- Multiple Days

- Intermediate

- $501-chiliad

Fiber cement is tougher than other materials

When you want the archetype wait of wood siding coupled with lifetime durability, fiberboard cement siding may well be your best choice. Fiberglass cement siding is a composite fabricated of Portland cement, silica and woods cobweb. Once painted, it looks almost identical to woods. It'due south available in many styles and widths, both polish and forest textured, and yous still get the well-baked joints and details that'll brand your home's exterior stand out. In improver, it'due south highly rot and insect resistant, won't burn and paints beautifully.

Jaime Venzor has been in the siding business for more 15 years. He started out installing mostly vinyl, but now 80 percent of his work is cobweb cement. He earned his good reputation with his customers past doing things the right way, and he earned our thanks by sharing some of his knowledge with us. So read on and larn what Jaime thinks are the virtually important tips.

Agree the starter 1/4 in. downward

Nailing Basics

Fiberboard cement siding tin be hand-nailed, but considering information technology's so much harder and more brittle than wood, you lot accept to predrill holes near any edge. You can relieve yourself a bunch of time by using a pneumatic coil siding nail gun. Unfortunately, a siding gun will set you back twice every bit much as a 15-gauge trim gun, and it's only half equally versatile, and then if installing fiber cement isn't your full-time gig, yous may want to rent one (about $110 a week). Every manufacturer has specific nailing guidelines, only hither are some basic rules:

- Use 6d or 8d galvanized or stainless siding nails and install a unmarried smash nigh 1-in. down from the meridian edge at each stud, no more than than xvi in. apart. due north Nail lengths should be chosen so they penetrate a minimum of one-1/4 in. into the solid wood (wood sheathings like OSB and plywood count toward the 1-ane/4 in., but "soft" sheathings like fiber board and foam don't).

- Don't drive nails into the siding at an angle.

- Fastener heads should be snugged up against the siding, not driven into the surface.

- The end of each plank making upward a barrel joint needs to exist fastened to a stud.

- Nail butt joints last. That way you lot can tweak the ends of each plank then the bottom edges line up perfectly.

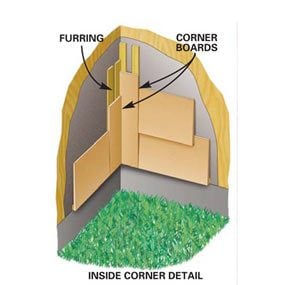

Preassemble the corners

Install fiber cement using a few special techniques

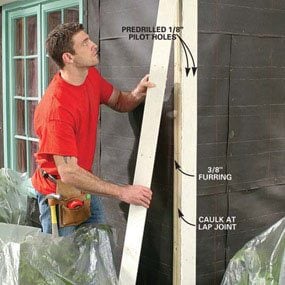

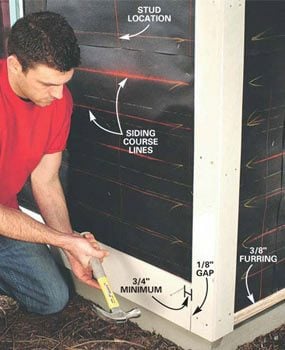

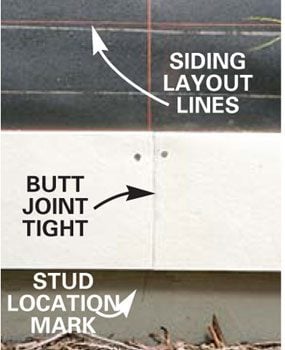

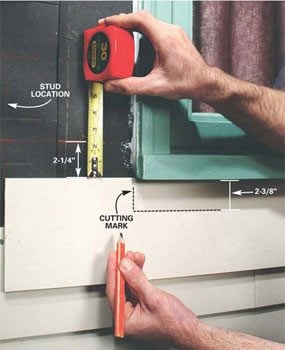

The layout process is exactly the same every bit for wood siding. Mark the stud locations with a pencil on the soffit and foundation where they won't exist covered past the edifice paper. Install the building newspaper (Photo 1), then follow your stud location marks and snap chalk lines (Photo two) to guide both your nailing and your placement of siding joints. We're also using cobweb cement trim boards. Since they're simply 7/xvi in. thick, rip 3/8-in. thick strips from treated 2-past lumber and apply them to fur out the frieze boards (Photo ii). Now they'll sit almost one/eight in. higher up the lap siding.

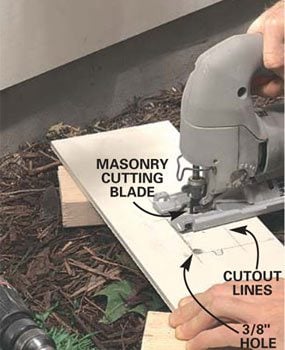

Cut the frieze board to length (Photograph three). Fiberboard cement siding is highly abrasive. Fifty-fifty a carbide tooth blade will last for simply function of the day. At home centers, yous can buy diamond blades made specifically for cutting fiber cement. These blades cut quickly and create less grit. Merely we had success with a less expensive dry-cutting, diamond masonry blade. Drill cutouts for electric boxes and pipes with regular twist $.25 or spade bits, and make interior or even curved cuts with a jigsaw fitted with a tungsten or carbide dust blade (these blades are available at abode centers and tile stores). Cutting fiberglass cement siding raises a lot of silica grit, then piece of work outside and wear a grit mask.

Nail up the frieze board by drilling 1/8-in. pilot holes and driving two galvanized box nails at each stud (Photo 4). Your smash length may vary from ours depending on the type of exterior sheathing used on your abode. In general, use nails that penetrate the studs at least 1 in. Drive the nailheads snug against the fiber cement board. If driven as well deep, the heads volition crush the fiber cement lath and reduce the nail's property ability. Don't nail fiber cement corners together (Photo 4). A smash driven into the border of a fiber cement lath will divide it.

Next make the outside corner (Photo 5), following the same steps as for the frieze boards. Be sure the bottoms of the corner boards cover about 1/2 in. of the foundation.

Tip:

If you don't have access to a tabular array saw, purchase a sheet of one/2-in.treated plywood and rip furring strips with a circular saw.

Caution!

Cut outdoors, wear a dust mask to avert breathing the dust, and keep others away.

Layout the siding courses

With the trim boards completed, lay out the siding courses with a story pole. (Run across "Making a Story Pole.") Concur the summit of the story pole snug confronting the frieze lath and mark out the siding courses (Photo 6) at all corners and around windows and doors. Following these layout marks, snap horizontal chalk lines. Recall that these layout lines represent the superlative of each siding course.

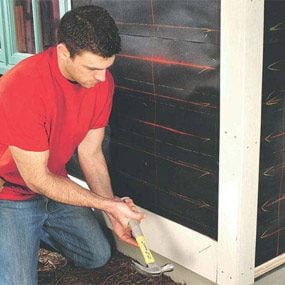

Rip and blast upwardly a 3/8-in. thick treated wood starter strip along the bottom of the wall (above the foundation). This strip will tip the first piece of siding to the proper angle. Measure and cut to length the offset piece of siding and boom it in place (Photo vii).

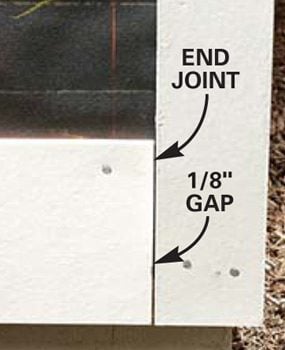

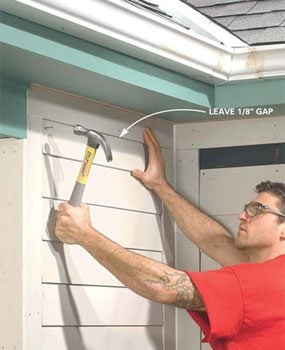

Leave a 1/8-in. gap where the end meets the corner board (Photograph 7, inset) and make sure the other end lands on a stud line. Install the next piece so its terminate butts lightly confronting the first (Photo seven, inset). Continue with the siding courses, adjustment the pinnacle edges to the layout chalk lines. Be sure to stagger the butt joints and then they don't lie on elevation of each other every bit yous work your way up.

Tip:

Pros use pneumatic coil nailers (you can rent 1) designed specifically for fiberboard cement siding. They cut nailing time in half. If you go this route, practice first to make sure the nailheads will be set up flush.

Making a Story Pole

Cut a straight 1×two so its length runs from the frieze board to the bottom of the showtime siding course. Mensurate upwardly from the lesser of the story pole to mark the full width of the showtime course of siding. Remember, this marking represents the acme of the siding slice, not the bottom of the second form.

From this point, brand marks up the pole at the recommended exposure for your siding. The top course should be at least ii-thirds the width of the lower courses. Check your layout marks against window and door openings and other features around the business firm, and suit the exposure to avoid having to rip narrow pieces.

When the terminal layout is OK, draw heavy lines on the face and both edges of the story pole using a square. Now concord the story pole tight confronting the frieze board at all corners and alongside windows and doors. Transfer the layout marks to the wall and snap chalk lines. This will ensure that all the siding courses go on straight and uniformly.

Remove the plastic final

Flash the butt joints

Spacing for Fiber Cement Lath Joints

Fiber cement boards don't expand and contract much, but leave a little room for expansion at the cease joints and then fill the gap with caulk. Barrel joints, still, should be nailed tightly together and should not be caulked. Make sure all butt joints are on studs, and stagger the butt joints equally you work your way up the wall.

Windows need drip cap and a gap on acme

It'due south a two-man job without siding gauges

Painted vs. Primed

We decided to use a prefinished product in this story, simply the other way to go is simple primed siding. That textile is primed and ready for you to pigment. Here are some facts to consider when making your conclusion.

The advantages of primed: Primed products cost 50 percent less than prefinished products. On-site painting looks better up shut because the impact-up pigment and caulked areas aren't every bit noticeable. Primed products are easier and less expensive to install.

The advantages of prefinished: The color on a prefinished product won't fade almost equally fast. Some finishes come with a fifteen-yr warranty. Only the all-time part of using a prefinished production is that afterward installation, you're done and not faced with painting an unabridged house.

Cutting fiber cement boards with a circular saw

Tons of fiber cement cut gadgets are available, just near jobs tin can be handled with but a steady eye and a standard circular saw fitted with a fiber cement bract. If you programme to hang a lot of cobweb cement, though, y'all'll want a chop saw with a proper bract that will let yous to cut several pieces at once.

Vinyl mounting blocks work best

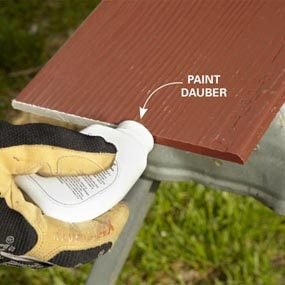

Paint, prime or caulk all cut edges

Every time you cut a plank, you create an exposed surface that has no primer or paint to protect information technology from the elements. If a cut edge is going to butt upward confronting a corner post or trim board, it gets caulked. If the cutting edge is part of a butt joint in the eye of the wall, it needs to be painted (effort to use factory edges on all butt joints). Planks that have been cut to fit over windows and doors besides need paint. Order paint kits and caulking to match both the trim and the siding colors. Your siding supplier should take access to both.

The Lowdown on Clearances

Fiberboard cement siding is non bulletproof—it volition deteriorate if exposed to water for a long fourth dimension. Information technology'south imperative that y'all honor the proper spacing between the siding and the roof surfaces and between the siding and the horizontal surfaces, such equally the ground or cement slabs and decks. Check with your specific manufacturer before y'all start. Hither are some general guidelines.

Leave:

- 1/8 in. to 1/4 in. between siding and trim

- 1/4 in. between siding and horizontal flashing

- 1 in. between the gutter and an side by side wall

- ii in. between siding and roofing, decks, patios, driveways, steps and walkways (using PVC trim boards is a good mode to reach these clearances)

- vi in. betwixt the siding and the basis.

Don't skip the kick-out flashing

Cutting fiber cement board effectually openings

Notch to get around windows and doors. Be sure to allow a 1/eight-in. gap where the siding meets the window trim and sill. This joint volition be caulked afterward. Blast the top edge of the siding along the windowsill at each stud. These nailheads will be exposed, but the pigment will cover them.

Notch to become around windows

Notch to go around windows and doors (Photos 8 and 9). Be sure to allow a ane/viii-in. gap where the siding meets the window trim and sill. This joint volition be caulked later. Smash the top edge of the siding along the windowsill at each stud. These nailheads volition exist exposed, but the paint volition cover them.

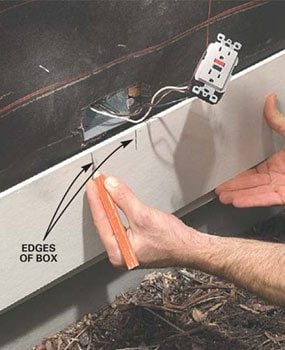

Water intrusion around wall penetrations can be a problem for any blazon of siding. Lay out and brand the cutout for the electric box (Photos 10 and eleven). The electric box embrace is gasketed to seal out water. For pipes, electrical entries and similar fixtures, fit the siding as tightly every bit possible and and then seal with a polyurethane caulk or not-hardening electrician's putty. Rip the elevation grade of siding to width and blast information technology upwards (Photo 12). Agree these nails one in. below the top edge. Again, these nailheads will exist exposed.

Buy the siding already primed. If you prime it yourself, use an brine resistant primer. Caulk all the joints with an acrylic latex caulk before applying the final coats of paint. Be sure the caulk fills the 1/eight-in. joint completely to go along information technology watertight. Cease-glaze with a 100 percentage acrylic latex paint.

Tip:

If you live in a region of high rainfall or the wall is highly exposed to water, slip a 3-in. broad strip of building paper backside butt joints. Be sure the lesser edge of the paper laps on summit of the lower course of siding.

Required Tools for this Project

Have the necessary tools for this DIY project lined up earlier you start—you lot'll salvage time and frustration.

Y'all'll besides need siding gauges, a fiber cement circular saw blade, a siding nailer and a 15 gauge trim nailer.

Required Materials for this Project

Avoid concluding-infinitesimal shopping trips by having all your materials ready ahead of fourth dimension. Here's a list.

Originally Published: February xx, 2018

Source: https://www.familyhandyman.com/project/how-to-install-fiber-cement-siding/

Posted by: winnerherfin1968.blogspot.com

0 Response to "What Type Of Nails For Cement Siding"

Post a Comment